| |

Teacher Logbook - NOAA Ship Ron Brown

| |

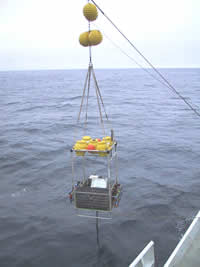

The elevator, loaded with experiments,

is deployed from the ship prior to

dive

R629. The instruments (experiments) were placed at Cloud vent on the

'98

lava

flow.

Cloud vent is in the background, surrounded by scientific experiments

and

gear.

The box in the center is a biology box (bio-box), which was used to

transport

the arrays to the elevator after their one-week deployment. The colorful

rectangular object on the right is a larval settlement array. The

tube

lying in

front of the bio-box is a larval trap. Two larval settlement arrays

and four

larval traps remain at Cloud for a one-year experiment |

|

Jeff Goodrich's Sealog:

Axial Volcano - 1998 lava flow

July 27, 2001

Deploying

and recovering instruments from the ocean floor is no easy task.

It

takes many skilled people and a lot of ingenuity. The science party brought

along two PMEL engineers, Chris Meinig and Nick Delich, who perform a

multitude

of tasks while on board and in the office (where they design and test

the

instruments needed for research cruises). The engineers are assisted by

Bruce

Cowden, the chief bosun, and the ROPOS crew while preparing the instruments

for

deployment and recovery. Their biggest challenge thus far was to overload

an

aluminum-rail elevator three times its maximum load, deploy it, sink it,

unload

it, load it back up, release it from the bottom, and recover it all during

daylight hours. It's nearly impossible to see and recover even brightly

colored

objects at night.

Working with

biological oceanographer Anna Metaxas, their first task

involved

reinforcing the aluminum-rail elevator by wrapping it in a nylon sling

to

make

the maximum load-carrying capacity higher. Next, a spreadsheet was designed

to

calculate the weight of the instruments plus the elevator in air and under

water. This is tricky because there's no easy conversion between the two.

Different materials weigh different percents of their air weight, once

in

water.

With the total weight calculated for deployment, they then calculated

the

total

weight during recovery for the instruments that were coming up from the

seafloor.

Next, the

correct buoyancy is calculated for the given weight, and a number

of

large yellow floats are attached to the elevator to raise it from the

seafloor.

With buoyancy added, they must then calculate how much weight must be

added

to

sink the elevator to get it down to the bottom during deployment. A weighted

railroad-car wheel is attached to the underside as an anchor for sinking.

To

raise the elevator off the bottom, an acoustic release is added to free

it

from

the railroad wheel anchor. The instruments in the elevator need to be

secure

for

the ride up or down but also be accessible by the limited dexterity of

ROPOS.

Sound complicated? It is. That's why we have engineers.

With the

elevator finally ready, they deployed it this morning with no

problems.

All the new experiments/instruments were deployed on the bottom, where

they

will spend the next year. Experiments that were finished were placed in

the

elevator. Dive R629 was a success, at least we hope so, as the elevator

is

still on its way to the surface. When the experiments are safely on board,

we

will all breathe a sigh of relief.

|

|